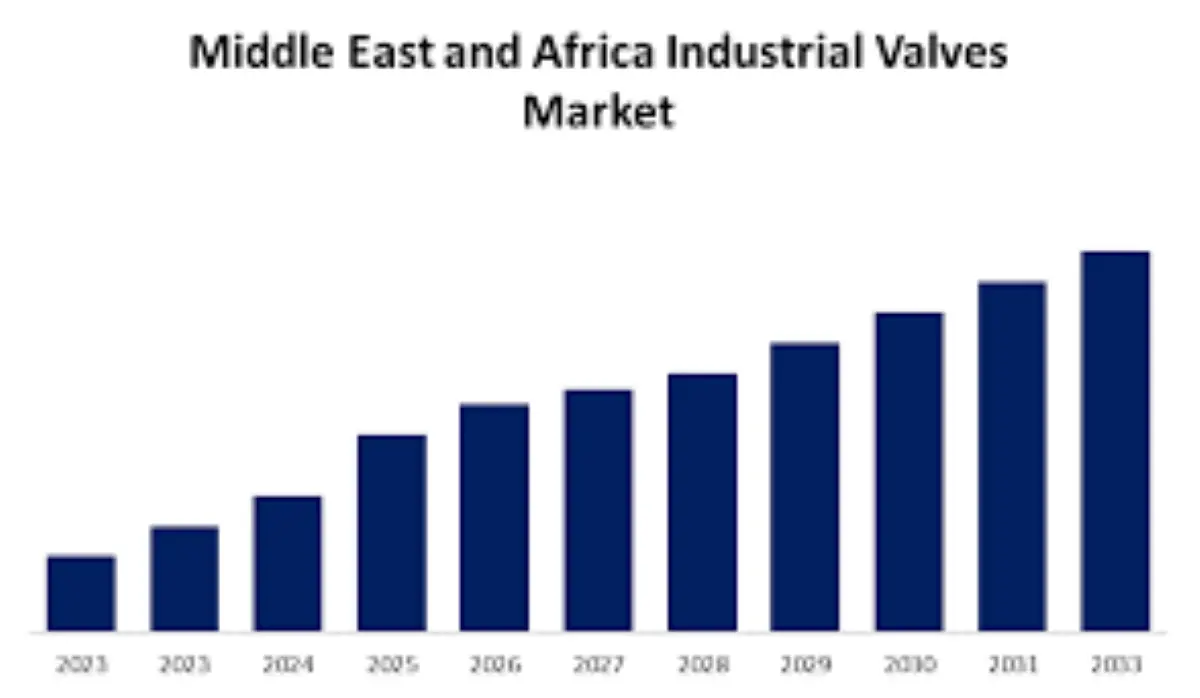

Trends in Middle East & Africa Demand for Butterfly Valves

1. Market Overview: A Region of Rising Industrial Momentum

The Middle East and Africa (MEA) have become two of the most dynamic regions for Industrial Valve demand, driven by rapid infrastructure expansion, urbanization, and ongoing energy investments.

Once considered traditional markets dominated by oil and gas, these regions are now transforming into diversified industrial hubs—creating new opportunities for Butterfly Valves in water management, power generation, and process industries.

1.1 Growth Drivers

- Water scarcity and treatment needs– Water shortage remains a pressing issue, especially in Gulf states. Desalination, wastewater treatment, and large-scale irrigation projects are multiplying, driving significant valve demand.

- Infrastructure and urbanization in Africa– Across Africa, governments are investing in roads, power plants, industrial parks, and water networks. These initiatives rely on robust fluid-control systems, with Butterfly Valves favored for their compact size, affordability, and easy maintenance.

- Energy diversification and renewables– New energy projects, such as solar and hydrogen production in the Middle East, are generating additional needs for precision control equipment, including high-performance Butterfly Valves.

- Advances in materials and automation– The adoption of stainless steel, alloy coatings, and automated actuators is improving reliability and lifespan, making Butterfly Valves suitable for harsher or more demanding conditions.

1.2 Challenges in the Market

While opportunities are vast, several challenges persist:

- Regulatory and compliance risk– Each country has different standards, and failure to meet certification requirements (API, ISO, CE, etc.) can block market entry.

- Intense competition– Global valve brands compete with low-cost regional suppliers, pressuring pricing and delivery timelines.

- Limited technical capability in some regions– Poor installation or maintenance often causes leakage and vibration, leading to performance issues.

- Logistics and currency volatility– Inland African countries face high transportation costs and foreign exchange fluctuations, affecting margins and payment reliability.

Despite these hurdles, companies that emphasize quality, service, and adaptability continue to gain market share.

2. Regional Demand Characteristics

2.1 Key Application Sectors

| Sector | Main Requirements | Valve Characteristics |

| Water & wastewater | Corrosion resistance, low maintenance | Manual or semi-automatic Butterfly Valves with rubber or epoxy linings |

| Desalination & seawater transfer | High corrosion resistance, tight sealing | Stainless steel or alloy valves with PTFE or duplex coatings |

| Oil, gas & petrochemical | High temperature and pressure, zero leakage | Triple-offset or metal-seated Butterfly Valves with automation |

| Power generation & cooling | Reliability, endurance | Large-diameter valves for cooling and steam systems |

| HVAC & building systems | Compactness, quick response | Electrically actuated Butterfly Valves |

| Chemical & manufacturing | Compatibility with various media | Lined or coated valves with chemical resistance |

Across most markets, manual Butterfly Valves remain mainstream due to cost advantages. However, thefastest-growing sub-segment is actuated Butterfly Valves—electric, pneumatic, or hydraulic—driven by industrial automation and remote control needs.

2.2 Material, and Automation Trends

- Materials– Carbon steel with internal coatings, stainless steel, and high-nickel alloys are increasingly used for durability and corrosion resistance.

- Sealing technologies– EPDM, PTFE, fluororubber, and metal seals ensure long-term performance under varying pressure and temperature.

- Automation– The adoption of electric and pneumatic actuators is accelerating, especially in water and oil projects seeking centralized control.

- Smart valves– Integration with SCADA, IoT, and predictive maintenance systems is emerging in advanced projects in Saudi Arabia and the UAE.

Triple-offset butterfly valves, known for their metal-to-metal seal and zero-leakage performance, are gaining traction in refineries and power plants, replacing traditional gate and globe valves in certain applications.

3. Market Outlook: Opportunities and Growth Directions

3.1 Key Trends to Watch

- Shift from manual to automated control– Operators are prioritizing smart valve systems that allow remote monitoring, reducing maintenance costs and downtime.

- Rising share of high-performance valves– Triple-offset and metal-seated butterfly valves are gaining favor in critical service conditions.

- Localization and warehousing– Shorter lead times and regional service centers are becoming decisive competitive advantages, especially in Africa’s inland markets.

- Lifecycle service and technical support– Clients increasingly value suppliers offering installation guidance, training, and after-sales maintenance.

- Green and energy-efficient solutions– Eco-friendly materials, low-emission sealing systems, and recyclable components are being prioritized in water and renewable energy projects.

4. Strategic Recommendations for Valve Exporters

To succeed in the MEA butterfly valve market, companies must combine technical reliability, localized service, and strategic market focus.

4.1 Build a Diversified Product Line

- Offer a range of butterfly valves—from standard wafer and lug types to triple-offset and high-performance designs.

- Balance cost and qualityaccording to market segment: economical options for developing areas, premium models for high-spec projects.

- Use modular designsto simplify production, spare parts management, and maintenance.

4.3 Strengthen Local Presence

- Set up regional warehouses or distribution hubsto shorten delivery times and reduce shipping costs.

- Partner with local agents or system integratorsfor sales, installation, and after-sales support.

- Maintain a spare-parts and service planto ensure reliability and quick response to client needs.

4.4 Emphasize Quality and Certification

- Align products with ISO, API, and CEstandards to meet international project requirements.

- Provide technical consultation and on-site trainingto enhance client trust.

- Offer clear warranty termsand responsive after-sales support to strengthen reputation.

4.5 Marketing and Branding

- Highlight successful project case studiesin the region, such as power plants, desalination stations, or water networks.

- Attend local exhibitionsand industry conferences to build visibility.

- Develop localized digital marketing—including English, Arabic, and French content—to reach diverse customer bases.

- Offer multilingual customer support for smoother communication.

4.6 Manage Risk

- Protect against currency and payment riskusing reliable international banking instruments.

- Conduct legal and political due diligencebefore entering new markets.

- Diversify customer portfoliosto avoid over-dependence on any single country or project.

5. Conclusion

Every market, no matter how complex, is ultimately shaped by vision—the courage to invest, to innovate, and to connect. For the valve industry, the Middle East and Africa are not merely destinations for products, but destinations for progress. Each project completed, each system optimized, moves the region one step closer to a smarter and more sustainable industrial era—and those who help make it possible will define the next chapter of global engineering.