The Heroes of Flow Control: Water Valves Powering Modern Infrastructure

Water is the lifeblood of our planet and our civilization. Its reliable, safe, and efficient management – from pristine source to our taps, through complex industrial processes, and back into the environment – depends heavily on a critical, often overlooked component: Water Valves. Far from simple taps, these precision-engineered devices are the essential workhorses controlling the flow, pressure, and direction of water across countless applications.

More than Just On/Off: The Diverse Roles of Water Valves

While basic shut-off is a fundamental function, modern Water Valves perform a sophisticated symphony of tasks:

Flow Regulation: Precisely controlling the volume of water passing through a system (e.g., pressure reducing valves, globe valves).

Pressure Management: Protecting pipelines and equipment from damaging surges (pressure relief valves) or maintaining consistent pressure levels.

Direction Control:Ensuring water flows only in the intended direction (Check Valves, non-return valves).

Isolation & Maintenance:Safely isolating sections of pipe for repair or replacement without draining entire systems (Gate Valves, ball valves).

Throttling:Gradually adjusting flow rates for process control (Butterfly Valves, globe valves).

Preventing Backflow: Safeguarding potable water supplies from contamination (backflow prevention assemblies).

The specific demands of an application dictate valve selection. Major categories include:

Gate Valves:Primarily for isolation. A sliding gate provides a tight seal in the fully open or closed position. Ideal for straight-line flow with minimal pressure drop when open.

Globe Valves: Excellent for precise throttling and regulation. Their spherical body and plug/disc design allow fine flow control, though they create higher pressure drops.

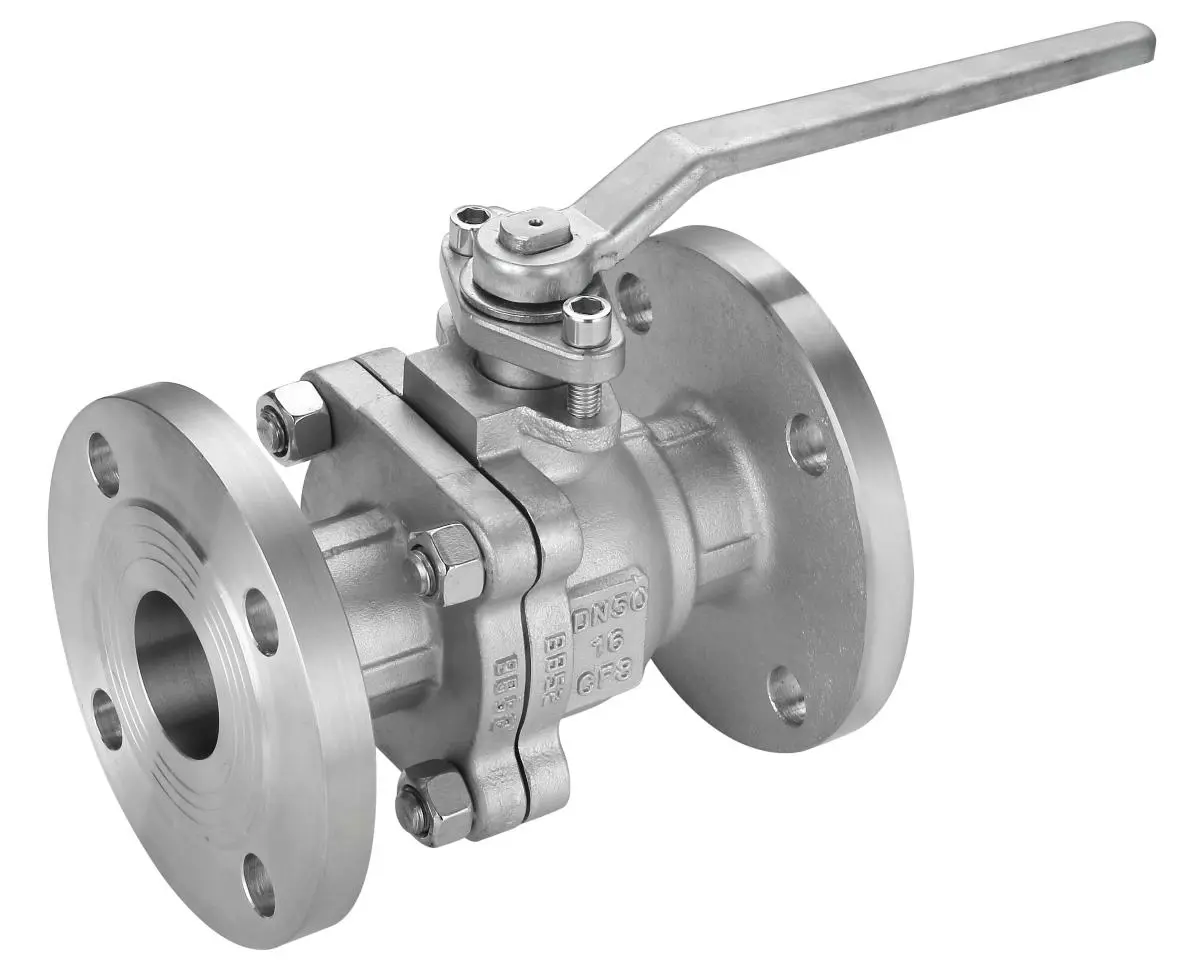

Ball Valves: The workhorse for quick shut-off. A rotating ball with a bore offers low torque operation, tight sealing, and minimal pressure drop. Highly versatile.

Butterfly Valves:Compact and cost-effective for large pipe diameters. A rotating disc controls flow. Excellent for moderate throttling and shut-off where space is limited.

Check Valves (Non-Return Valves): Automatic valves allowing flow in one direction only, preventing backflow. Essential for pump protection and system integrity.

Diaphragm Valves: Use a flexible diaphragm to regulate flow. Ideal for slurries, corrosive fluids, or applications requiring high purity (e.g., pharmaceuticals, food & beverage) as the fluid only contacts the diaphragm and body lining.

Pressure Reducing Valves (PRVs): Automatically reduce incoming high pressure to a safe, constant downstream pressure, protecting appliances and pipework.

Pressure Relief Valves (Safety Valves): Critical safety devices that automatically open to release excess pressure if a system over-pressurizes.

The Water Valve industry is dynamic, driven by several key factors:

Aging Infrastructure: Massive global investments in replacing and rehabilitating old water and wastewater networks create significant demand for reliable, long-lasting valves.

Water Scarcity & Efficiency: Growing pressure on water resources necessitates valves that minimize leakage (e.g., low-torque, bubble-tight seals) and enable precise water management in agriculture and industry.

Stringent Regulations: Increasingly strict standards for water quality (e.g., lead-free requirements like NSF/ANSI 61, WRAS), backflow prevention, and emissions control drive innovation in materials and design.

Smart Water Networks: The rise of IoT and digitalization demands "smart valves" equipped with sensors (pressure, flow, position, temperature) and actuators for remote monitoring, control, predictive maintenance, and data-driven optimization.

Material Advancements: Development of superior corrosion-resistant alloys (duplex stainless steel, super duplex), advanced polymers, and specialized coatings extend valve life in demanding environments like seawater desalination or aggressive wastewater.

Focus on Sustainability: Manufacturers emphasize energy-efficient actuation, reduced fugitive emissions (low-emission packing/seals), recyclable materials, and designs promoting water conservation.

Water valves are far more than simple fittings; they are sophisticated, vital components underpinning the safety, efficiency, and reliability of our entire water cycle. From ensuring clean drinking water reaches our homes to enabling complex industrial processes and protecting the environment through effective wastewater treatment, valves perform indispensable functions. As the industry evolves, driven by digitalization, sustainability imperatives, and infrastructure renewal, innovation in valve technology – smarter, tougher, leak-proof, and more efficient – will remain crucial for managing our planet's most precious resource effectively and building resilient water systems for the future. The next time you turn on a tap, remember the intricate network of valves silently making it possible.