How Valve Manufacturing Boosts Pump System Efficiency

In today’s world, “energy saving and emission reduction” is no longer just a buzzword—it’s a global priority. From governments setting ambitious climate targets to industries under pressure to lower costs and reduce their carbon footprint, the demand for efficient technologies has never been stronger. Pump systems, often described as the “hearts” of industrial facilities, account for an astonishing 20–25% of total electricity consumption in many countries. That means nearly one out of every four kilowatt-hours of electricity goes directly into running pumps.

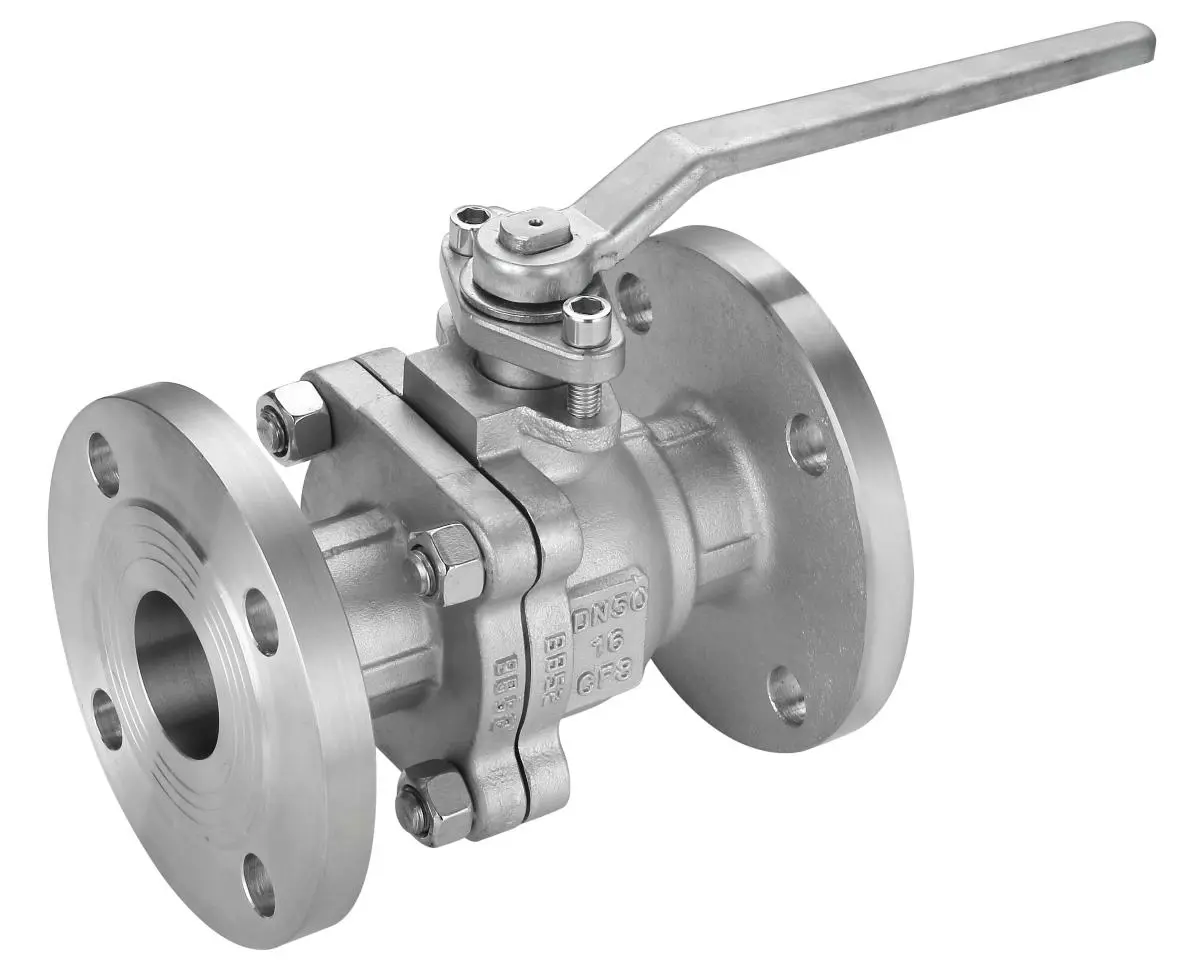

Given this enormous share of energy use, improving pump efficiency is a key strategy for meeting sustainability goals. But when people talk about pump efficiency, they often overlook a critical piece of the puzzle: valves. Far from being simple on/off switches, valves regulate flow, pressure, and energy transfer in a system. The way they’re designed, manufactured, and integrated with pumps can make a huge difference in overall energy performance.

In this article, we’ll explore how valve manufacturing plays a vital role in upgrading pump system efficiency under the background of energy saving and emission reduction. We’ll break it down into materials and manufacturing improvements, design innovations, insulation and loss control, and finally, system-level integration with pumps and intelligent controls.

Why Valves Matter in Pump System Efficiency

Traditional pump systems often rely on valves to control flow by restricting or opening passages. While this is simple and widely used, it comes at a cost. When a valve is partially closed, it creates resistance, which means the pump has to work harder. The result? A significant amount of energy is wasted as friction and heat instead of being used for useful fluid delivery.

For example, a DN100 steam valve operating at 200°C without proper insulation can lose energy equivalent to eight tons of standard coal per year—translating into thousands of dollars in economic losses. Multiply that across hundreds of valves in an industrial facility, and the scale of waste becomes obvious.

Valves also contribute to pressure drops within the system. The bigger the pressure drop, the harder pumps must work to maintain required flow rates. In some cases, valve-related losses account for a major portion of total system head. Clearly, making valves smarter and more efficient isn’t just nice to have—it’s essential for energy reduction.

Innovation in Valve Manufacturing

1. Material Innovation and Manufacturing Processes

Valve manufacturers are increasingly investing in high-performance materials to reduce energy loss and extend equipment life. Traditional cast iron valves, while cheap, suffer from corrosion, erosion, and poor resistance to cavitation. By contrast, duplex stainless steel offers higher uniformity, finer grain structures, and excellent resistance to corrosion and wear. This not only lowers maintenance costs but also improves flow efficiency, since smoother surfaces reduce turbulence.

In terms of manufacturing, advanced casting and CNC machining techniques allow engineers to design more precise flow channels inside valves. Better flow paths mean reduced vortices, smoother transitions, and ultimately lower pressure losses. Surface hardening technologies are also gaining traction, making sealing surfaces more durable and minimizing internal leakage—a subtle but often overlooked source of wasted energy.

2.Structural Design and Flow Optimization

The structure of a valve determines how fluid behaves when it passes through. Thanks to computational fluid dynamics (CFD), designers can now simulate fluid flow before even building a prototype. By creating streamlined bodies and optimized trim components, they can minimize turbulence and achieve smoother passage.

One cutting-edge approach is applying three-dimensional flow theories to valve internals. Instead of flat or symmetric geometries, engineers design irregular curved surfaces that guide fluid naturally, reducing cavitation, vibration, and unnecessary energy loss. The result? Valves that not only save power but also operate more quietly and last longer.

Another trend is modular design. With standardized interfaces and interchangeable components, manufacturers can offer tailor-made solutions without compromising efficiency. This flexibility allows systems to be fine-tuned for specific industries—from petrochemicals to water treatment—without the inefficiencies caused by “one-size-fits-all” solutions.

3.Insulation and Heat Loss Control

For valves operating under high-temperature conditions, insulation is a game-changer. Without it, a single valve can waste enormous amounts of energy. Traditional fixed insulation methods, however, are bulky, hard to maintain, and degrade quickly.

Enter flexible removable insulation jackets. Using advanced materials such as nano aerogels—with thermal conductivity as low as 0.020 W/(m·K)—these jackets dramatically reduce heat losses compared to conventional rock wool. Even better, they can be removed and reinstalled within 15 minutes, withstand dozens of cycles, and last up to a decade.

In real-world terms, this means cutting annual heat loss from the equivalent of eight tons of coal down to just one ton or less. Maintenance crews save hours of labor, safety improves, and production runs more smoothly—all while conserving energy.

System-Level Integration: Valves and Pumps Working Together

1.Coordinated Pump-Valve Regulation

One major limitation of traditional systems is that pumps and valves are often controlled separately. The pump sets the flow, and the valve adjusts it afterward—an inherently inefficient setup.

Modern energy-saving strategies emphasize pump-valve joint regulation. By coordinating pump speed and valve opening, the system can consistently operate near its best efficiency point. Technologies like electro-hydrostatic actuators (EHAs) are leading this charge, enabling precise control of pump flow and valve positions to reduce losses.

Another widely adopted solution is combining variable frequency drives (VFDs) with valve adjustments. In large flow changes, the VFD adjusts pump speed. For fine-tuning, the valve makes small adjustments. This “division of labor” balances efficiency with responsiveness, achieving significant energy savings.

2.Intelligent Control and Predictive Maintenance

The rise of industrial IoT has transformed valves into smart devices. By embedding sensors that track pressure, temperature, and flow, smart valves can continuously monitor system performance. When connected to intelligent controllers, they can automatically adjust settings to maintain optimal operation.

Advanced algorithms like Model Predictive Control (MPC) take things further. Instead of reacting to changes, they anticipate them, adjusting pump-valve strategies proactively. For instance, if the system detects an upcoming change in demand, it can lower energy use before the spike occurs.

Data analytics also enables predictive maintenance. By analyzing valve performance trends, systems can forecast when a valve will start leaking or losing efficiency. Instead of waiting for a breakdown—or wasting energy for months—operators can schedule timely interventions. Studies show predictive maintenance can cut energy waste by more than 30%.

Real-World Impacts and Benefits

When these innovations come together, the benefits are clear:

- Lower operating costs: Reduced energy use translates directly into smaller utility bills.

- Extended equipment life: With less wear and better materials, valves and pumps last longer, lowering replacement costs.

- Improved safety: Proper insulation and predictive monitoring reduce risks of overheating, leaks, or sudden failures.

- Environmental benefits: Cutting unnecessary power consumption lowers greenhouse gas emissions, helping industries align with carbon neutrality goals.

For industries like petrochemicals, power generation, water treatment, and steel manufacturing, the impact can be massive. Even a 10% improvement in pump system efficiency across a facility can save millions in energy costs annually while significantly reducing emissions.

Conclusion

Energy saving and emission reduction aren’t abstract ideas—they’re practical goals that require concrete action. Pump systems, as major energy consumers, represent one of the biggest opportunities for improvement. But pumps can’t achieve efficiency alone; valves, as the gatekeepers of flow and pressure, play an equally vital role.

By advancing materials, designs, insulation methods, and smart integration strategies, valve manufacturers are proving that they are not just component suppliers but active partners in the global energy transition. For industries looking to cut costs, boost reliability, and meet sustainability targets, upgrading valves is one of the smartest moves they can make.