Common Butterfly Valve Issues & How to Solve Leakage, Sticking, and Vibration

Butterfly Valves are everywhere—from water plants and HVAC systems to chemical factories and ships—because they're compact, affordable, and quick to operate. A simple quarter-turn moves the disc from fully closed to fully open, controlling flow with minimal fuss. But like any piece of equipment, they can have their "off" days.

Three problems tend to pop up the most: leakage, sticking, and vibration. They might sound small, but left unchecked, they can snowball into costly repairs or system downtime. The good news? Most of the time, these problems are not mysterious—they have clear causes and straightforward fixes. In this article, we'll break down each issue in plain language, so you'll know what's happening, why it's happening, and exactly what to do about it.

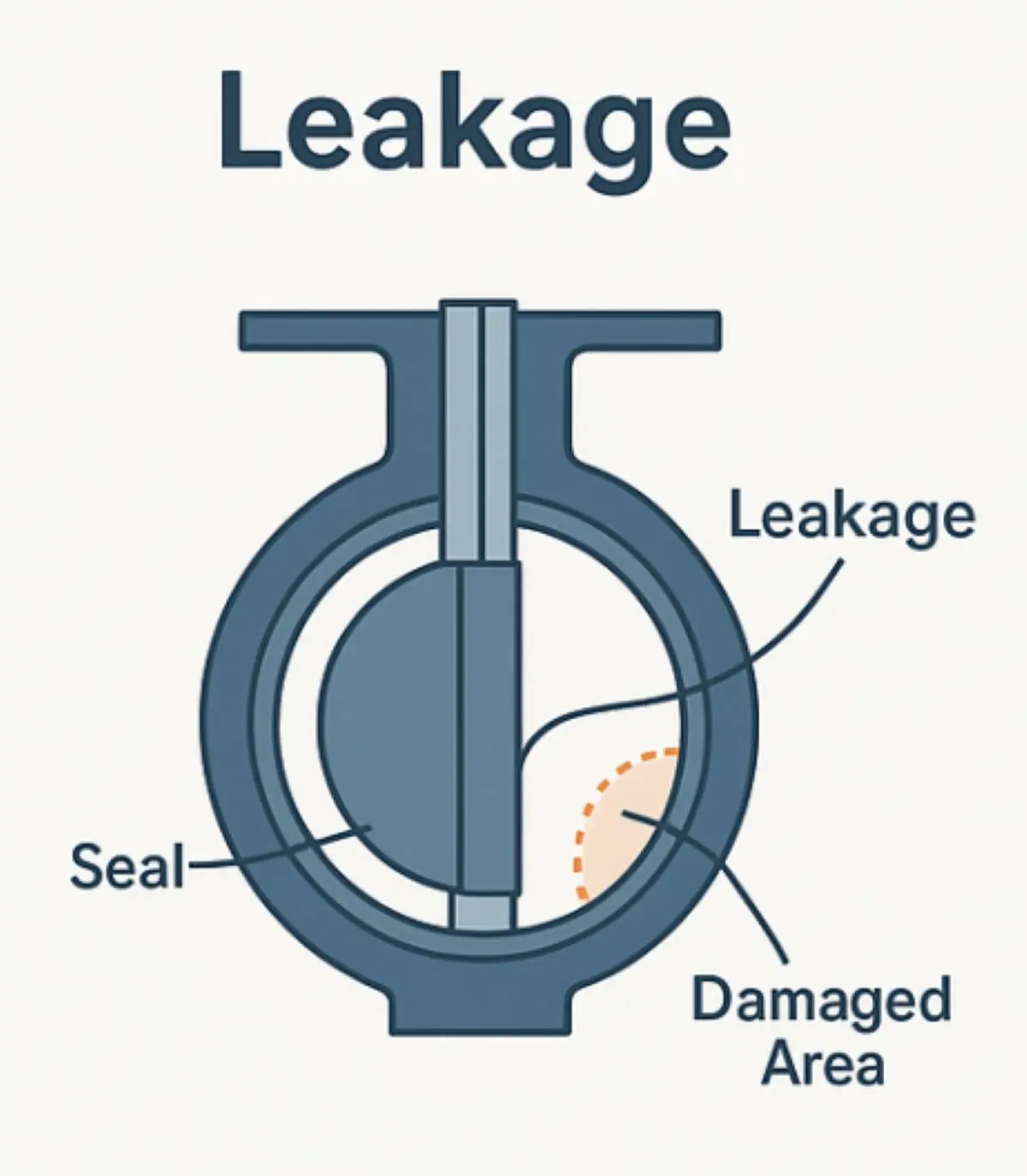

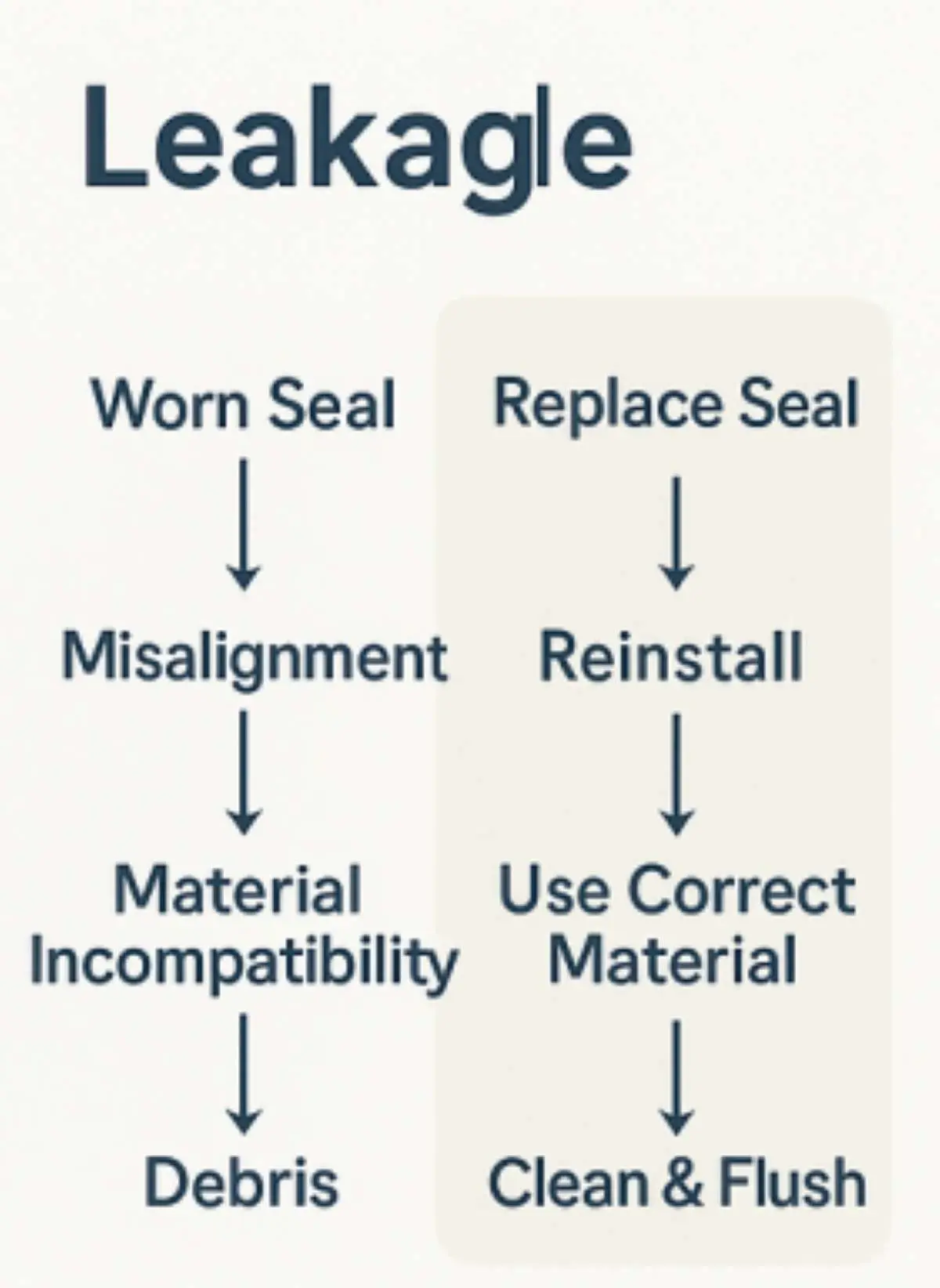

Leakage

If your Butterfly Valve is leaking, the first thing to remember is—it's not always the valve's "fault." Most leaks come from worn-out sealing parts, like the elastomer seat or the soft seal that hugs the disc when closed. Over years of operation, these parts face constant pressure, chemical exposure, or heat cycles, and eventually they lose their shape or flexibility. Sometimes, gritty particles in the fluid scrape away at the seal, leaving tiny channels for fluid to escape. Corrosion can also be the silent culprit, eating away at the metal around the seal until it can't hold pressure. And then there's the human factor—if the valve was installed off-center or the bolts were tightened unevenly, you might get leakage from day one.

The fix? Step one is to find exactly where the leak is coming from. If it's the seal, replacement is your best bet. Choose the right material for the job—EPDM works for water, PTFE resists harsh chemicals, and metal seats handle high heat and abrasives. Quick patches like grease or sealant might slow a leak for a short time, but they're just buying time, not solving the problem. If installation was the issue, remove the valve, center it properly between the flanges, and tighten the bolts in a crisscross pattern to even out the pressure.

If you want to stay ahead of leaks, regular check-ups are key. Flush the pipeline now and then to clear out debris, check the stem packing for looseness, and replace seals before they completely fail. For critical systems, some operators even use leak detection sensors to catch issues before they get serious. Think of it as "routine dental care" for your valve—small visits keep you from big problems later.

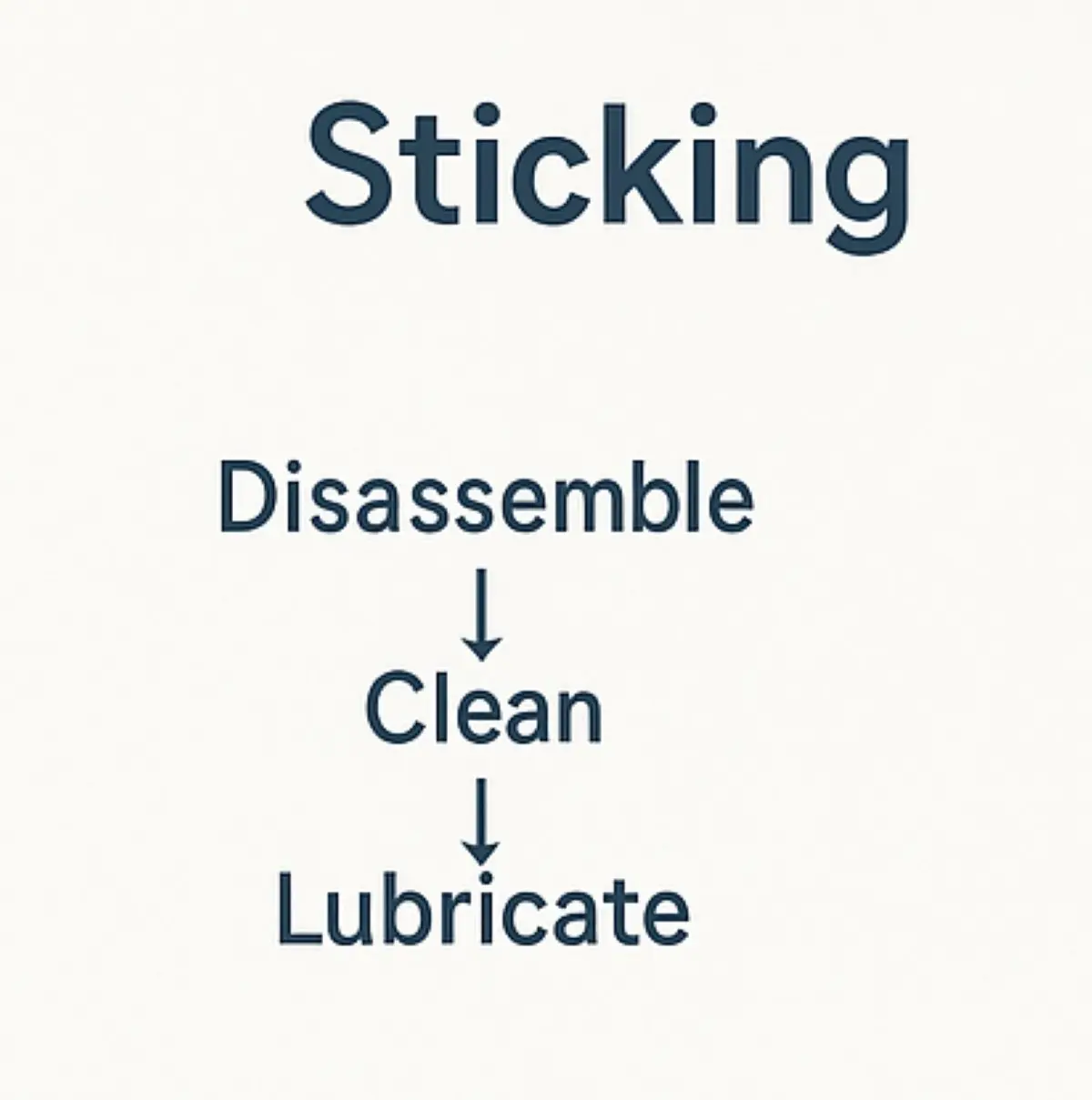

Sticking

A sticking Butterfly Valve is a real headache—especially if you're running an automated system. The tell-tale sign is when the disc feels stiff or refuses to budge, whether you're opening or closing it. The number one cause? Debris. Rust flakes, sediment, welding spatter—anything in the line can end up lodged in the wrong place. Over time, this build-up can literally wedge the disc in place. Lack of lubrication is another common offender; when stems and bearings dry out or corrode, you're basically grinding metal against metal. Over-tightened packing can do it too—clamping down so hard on the stem that it can't move freely. And of course, worn or bent parts will make the problem worse.

Fixing a sticky valve often starts with giving it a good "spring cleaning."Shut down and depressurize the system, take the valve apart, and get rid of any debris. Use clean water, compressed air, or the right cleaning solution for your process. Then, apply the proper valve-grade lubricant to all moving parts—just enough to keep things sliding smoothly without attracting more dirt. If the packing is too tight, loosen it slightly so the stem can turn without leaking.

If you've done all this and it's still sticking, it's time to check for mechanical damage. Replace any bent stems, worn bearings, or damaged discs. And to keep the problem from coming back, consider adding strainers upstream to catch debris before it reaches the valve. Also, make lubrication part of your maintenance routine—it's one of those small habits that saves big headaches.

Vibration

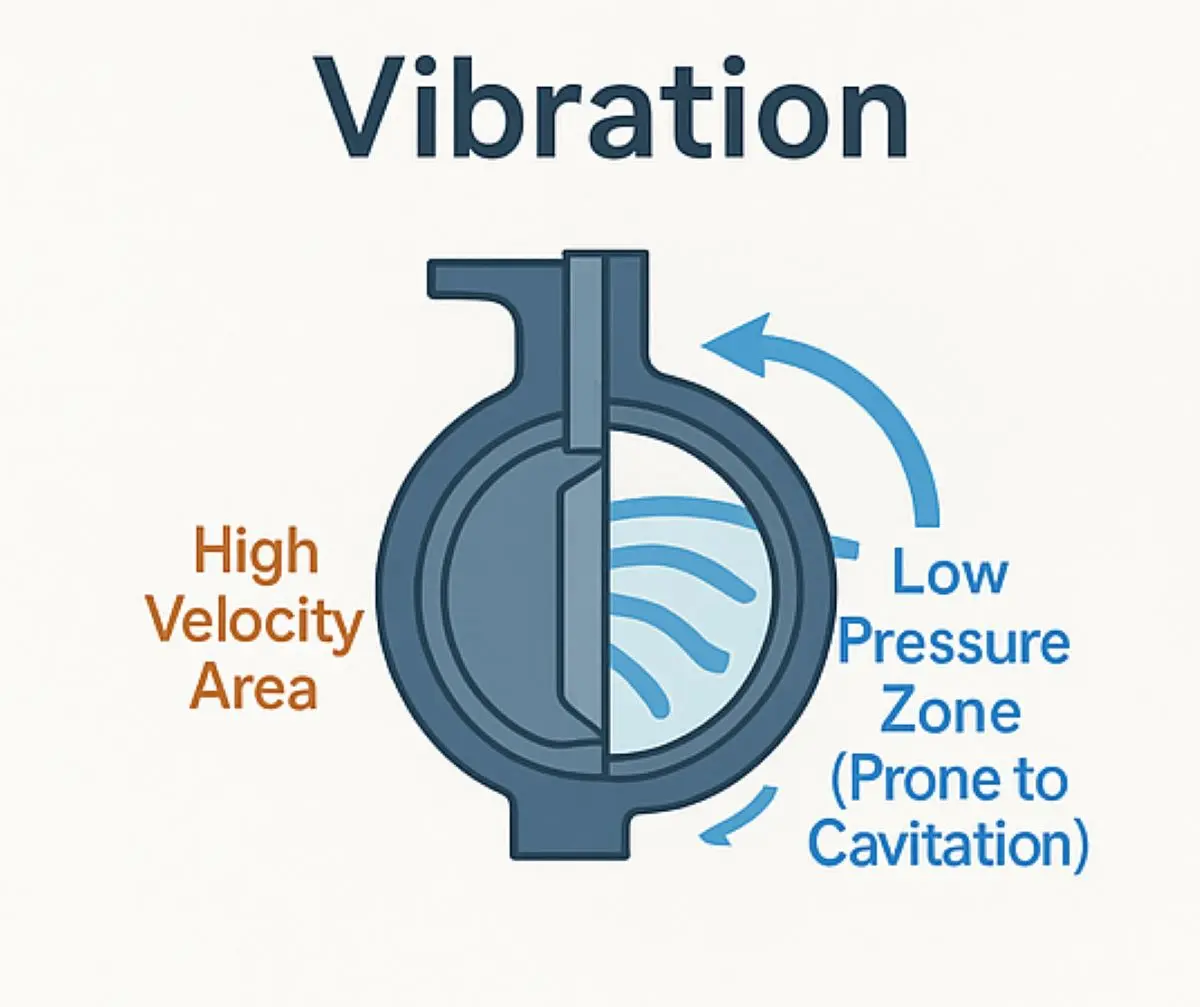

If your valve is rattling, shaking, or making a humming noise, you’re dealing with vibration. It’s less common than leaks or sticking, but it can be just as destructive if ignored. The root cause is usually turbulent flow—when the valve is only partly open, fluid rushes past the disc unevenly, creating swirling pressure zones. This can trigger cavitation, where vapor bubbles form and collapse with enough force to pit metal surfaces. Mechanical factors make things worse: loose bolts, poor pipeline support, or misaligned flanges let the valve move around under load. High flow velocities or pulsating pressures from pumps can crank up the vibration even more.

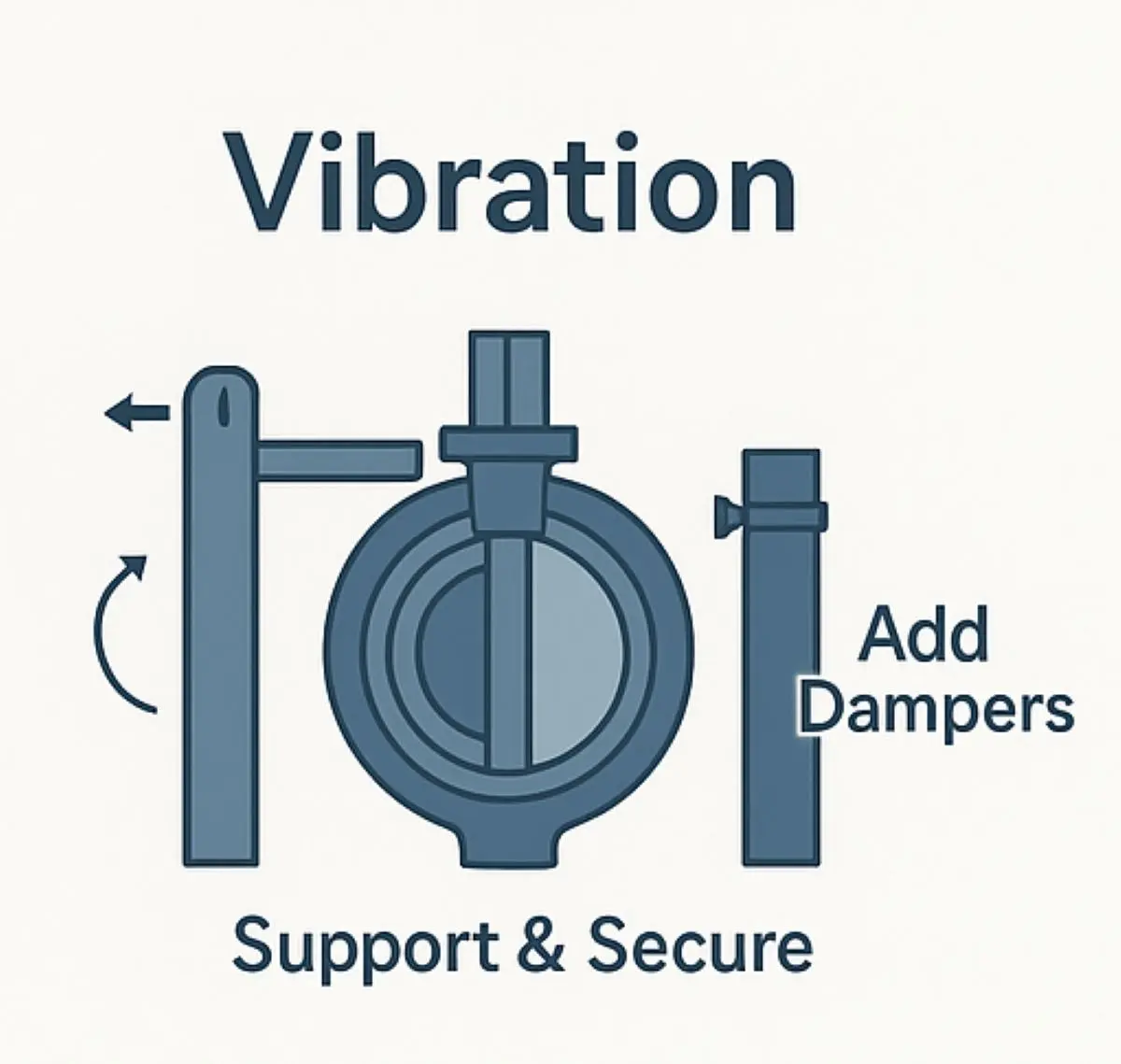

The first thing to check is the installation. Are all the bolts tightened to spec? Is the valve centered and aligned with the pipe? Is the pipeline supported well enough? Fixing these basics can often quiet things down. Then look at how you're operating the valve—try to avoid running it in a nearly closed position for long periods, as that's prime territory for turbulence and cavitation.

For chronic vibration problems, upgrading to a double-offset or triple-offset design can help, since they disturb the flow less. In systems with pulsating pressure, adding dampers or pulsation arrestors can smooth things out. And of course, regular inspections matter—if the seat, disc, or bearings are worn, replace them before the imbalance gets worse. The rule of thumb here: a quiet valve is a healthy valve.

Conclusion

Butterfly Valves are built to be tough, but even tough equipment needs some care. Leaks usually mean the seals are worn or something went wrong during installation. Sticking often comes down to debris or a lack of lubrication. Vibration points to flow turbulence or mechanical instability. The fixes aren’t rocket science—replace worn parts, clean and lubricate regularly, tighten and align during installation—but they make all the difference in performance and longevity.

By paying attention to these three common issues and handling them early, you can keep your valves working smoothly, protect the rest of your system, and avoid those unplanned downtime surprises. Think of it as giving your valves the same care you’d give any piece of equipment you depend on—because in the long run, that’s exactly what keeps the whole operation flowing.