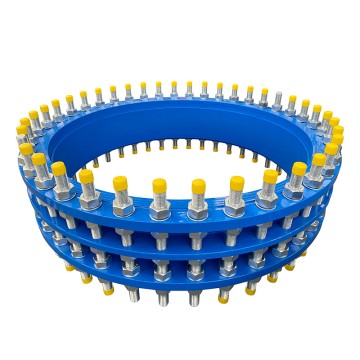

Premium Groove Butterfly Valves from Leading Factories & Exporters Worldwide

Are you in need of a dependable Groove Butterfly Valve for your operations? Our high-quality solutions are engineered for precision and durability, making them suitable for various industrial applications. As an OEM manufacturer, we pride ourselves on offering customizable valve options that cater to your specific needs. With extensive experience, NEWSTAR VALVE (ZHENGZHOU) CO., LTD. ensures our products adhere to the highest industry standards. We are committed to providing expert support throughout the purchasing process and beyond. Every project is unique, and our team is here to assist you in finding the ideal valve solution. Rely on us for performance and quality you can trust. Contact us today to enhance your fluid control systems with our Groove Butterfly Valves!Best Methods To Groove Butterfly Valve Is The Best Your End-to-End Solution

When it comes to selecting the right Butterfly Valve for your industrial needs, understanding the best methods to groove these valves ensures a reliable and efficient end-to-end solution. Butterfly Valves are widely recognized for their ease of operation, compact design, and capability to handle low to middle pressure applications. By implementing the correct groove techniques, manufacturers can enhance the performance and durability of these valves, making them suitable for a variety of environments. The grooving process involves creating precision grooves on the valve body, which aids in better sealing and reduces the chances of leakage. This is especially crucial in industries where safety and efficiency are paramount. By utilizing advanced materials and innovative manufacturing processes, valve producers can create Butterfly Valves that not only meet international standards but also contribute to lower maintenance costs and improved overall system performance. For global purchasers seeking high-quality Butterfly Valves, focusing on manufacturers with expertise in specific valve designs can lead to significant advantages. Collaborating with providers that specialize in large-size Butterfly Valves will ensure access to tailored solutions that fit unique system requirements. As the industry evolves, leveraging the latest technologies in valve production will set suppliers apart in delivering exceptional products that meet the demands of diverse industrial applications.

Best Methods To Groove Butterfly Valve Is The Best Your End-to-End Solution

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Grooving Machine | Utilizes a specialized machine for precise grooving of Butterfly Valve ends. | High precision and efficiency in grooving. | Initial investment cost can be high. |

| Hand Tool Grooving | Using hand tools for manual grooving of valve ends. | Cost-effective and requires minimal equipment. | Time-consuming and requires skilled labor. |

| Laser Grooving | Employs laser technology to create grooves with high accuracy. | Very precise, can be automated for mass production. | High equipment cost and maintenance. |

| CNC Grooving | Computer Numerical Control machining to groove valve ends. | High repeatability and precision. | Requires programming knowledge and CNC machine setup. |

| Ultrasonic Grooving | Uses ultrasonic waves to create micro-grooves in materials. | Very fine grooves, suitable for sensitive materials. | Limited to specific materials and applications. |

Top 3 Groove Butterfly Valve Guarantees Peak Performance Outperforms the Competition

E

Ethan Lee

I highly recommend this product. It’s reliable and the after-sales support has been phenomenal.

22 July 2025

G

Grace Turner

Highly satisfied with the product quality. The support team really knows their stuff and was incredibly responsive.

23 June 2025

H

Hannah Mitchell

This item has outstanding quality. The professionalism of the support staff made a real difference in my experience.

01 August 2025

L

Linda Brown

The craftsmanship of this product is remarkable. You can tell it’s made with care.

12 June 2025

L

Laura Hall

I was impressed by the quick response from their customer service team. They resolved my inquiry swiftly.

22 July 2025

A

Amy Martinez

Their customer support is truly world-class. They really know how to take care of their clients.

28 June 2025