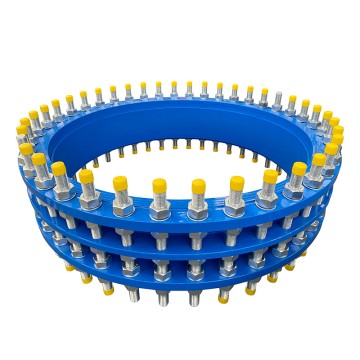

Top Flange Check Valve Manufacturers for Quality Solutions and Reliable Performance

Reliable flow control is essential, and our Flange Check Valve delivers just that. Engineered for optimal performance, this valve guarantees one-way flow in your piping system, effectively preventing backflow and protecting your equipment. Understanding the needs of your project, we provide competitive quotes customized for you. Constructed from high-quality materials, our Flange Check Valve adheres to industry standards for durability and efficiency. Each valve promises exceptional quality and dependable operation, making it a standout choice for any application. Rely on NEWSTAR VALVE (ZHENGZHOU) CO., LTD. for products that ensure long-lasting performance and seamless operations in your facility. For quotes and more information about our Flange Check Valve, please don't hesitate to reach out.Methods To choose Flange Check Valve Exceeds Industry Benchmarks in 2025

Choosing the right Flange Check Valve is crucial for ensuring optimal performance and compliance with industry standards. With the rising demands and technological advancements projected for 2025, it's essential to consider specific methods that can help procurement specialists select valves that go beyond mere industry benchmarks. One important method is to assess the material specifications of the check valve. Valves constructed from high-quality materials such as stainless steel or specially designed alloys can ensure durability and resistance to corrosion, which is particularly important in harsh industrial environments. Another method involves evaluating the design and manufacturing processes utilized in producing these valves. Advanced manufacturing techniques, such as precision casting and state-of-the-art machining, significantly impact the reliability and functionality of Flange Check Valves. Additionally, obtaining detailed performance data and testing certifications can provide insights into the valve’s reliability under various operating conditions. Engaging with manufacturers that embrace innovative technology and adhere to rigorous quality control measures can also be beneficial in sourcing top-tier Flange Check Valves. Lastly, collaborating closely with suppliers to understand the latest market trends and technological advancements can lead to better-informed purchasing decisions. Keeping abreast of regulatory changes and industry standards will further assist in selecting valves that not only meet but exceed operational expectations. By adopting these methods, global procurement professionals can ensure that they are investing in Flange Check Valves that provide superior performance and value, setting a new standard in industrial applications.

Methods To choose Flange Check Valve Exceeds Industry Benchmarks in 2025

| Method | Description | Industry Benchmark | Performance Metrics |

|---|---|---|---|

| Material Selection | Choosing the right materials to enhance durability and resistance. | Corrosion resistance rating of 9/10 | Lifespan exceeds 20 years in aggressive environments |

| Design Efficiency | Optimizing valve design for improved flow and reduced turbulence. | Pressure drop less than 0.5 bar | Flow coefficients above 150 |

| Testing Procedures | Implementing rigorous testing scenarios to ensure reliability. | Leakage rate under 0.01% | Successful operation at temperatures up to 250°C |

| Quality Assurance | Establishing stringent quality control measures throughout production. | ISO 9001 Certification | Defect rate below 0.5% |

| Supplier Selection | Choosing reliable suppliers with proven track records. | Supplier rating of 4.5/5 | On-time delivery rate of 95% |

How To Source Flange Check Valve in 2025 Products

G

Grace Turner

Highly satisfied with the product quality. The support team really knows their stuff and was incredibly responsive.

23 June 2025

E

Ella Thompson

Absolutely thrilled with this purchase. The quality is superb, and the support team was incredibly helpful.

10 July 2025

T

Thomas Anderson

The support team is always friendly and quite knowledgeable, making the whole experience enjoyable.

15 June 2025

S

Sarah King

Each time I interact with the customer service team, I feel like a valued customer.

25 July 2025

B

Brian Adams

Every detail in this product shows the level of expertise that went into its creation.

11 June 2025

G

George Murphy

The product quality is evident, and their service is unbeatable. I highly recommend them!

21 July 2025