Control Valve Sizing Guide: Price List & Trusted Exporter Information

In the realm of **Control Valve Sizing**, precision and reliability are crucial for OEMs, suppliers, and manufacturers. At NEWSTAR VALVE (ZHENGZHOU) CO., LTD., we offer custom solutions that cater to your unique requirements. Our control valves are engineered with advanced technology to ensure optimal performance across a variety of applications. With a wide range of sizes and specifications available, you can find the ideal solution for your project. Whether managing large-scale flow or making minor adjustments, our products are designed for efficiency and durability. Our dedication to exceptional service guarantees expert guidance and support throughout the selection process, enabling confidence in the reliability and efficiency of your control systems and helping your projects run seamlessly. Let's maximize the potential of your operations together!

Practical Methods To Control Valve Sizing From Concept to Delivery Global Reach

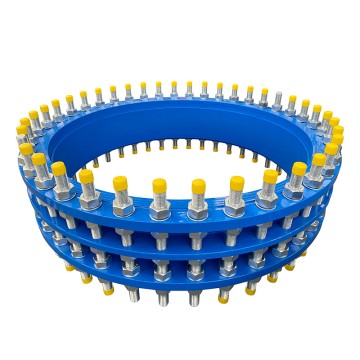

When it comes to valve sizing, the journey from concept to delivery is crucial for effective operations and optimal performance. Practical methods for control valve sizing involve a meticulous assessment of system requirements, including pressure, temperature, and flow rates. By leveraging advanced software and simulation tools, stakeholders can accurately determine the appropriate valve specifications needed for various industrial applications. This process ensures that the selected valves meet operational demands without compromising efficiency or safety. Collaboration plays a significant role in valve sizing, as engineers and procurement teams must communicate effectively to understand project scope and objectives. Engaging with manufacturers who specialize in low and middle pressure butterfly valves and Tilting Disc Check Valves adds value, ensuring that tailored solutions are developed based on specific requirements. By focusing on customization and flexibility, organizations can achieve better performance and longer service life for their systems. The global marketplace presents unique challenges and opportunities in valve manufacturing. Establishing strong relationships with reliable suppliers can streamline the procurement process, reduce lead times, and enhance quality assurance. Moreover, leveraging a manufacturer's expertise in large-size butterfly valves can improve the overall effectiveness of industrial operations, making partner selection a critical element in achieving desired outcomes. By implementing these practical methods, companies can enhance their procurement strategies and ensure successful project completion on a global scale.

Practical Methods To Control Valve Sizing From Concept to Delivery Global Reach

| Method | Description | Application Area | Expected Outcome |

|---|---|---|---|

| Flow Rate Calculation | Determine the required flow rate based on system needs. | Industrial piping systems | Accurate sizing, improved efficiency |

| Coefficient Selection | Identify appropriate flow coefficient (Cv) for valve. | Chemical processing | Optimized valve performance |

| Pressure Drop Analysis | Analyze pressure drop across valve and system. | Water distribution | Reduced energy consumption |

| Material Compatibility | Select correct materials based on fluid type. | Oil and gas sector | Enhanced durability and reliability |

| Regulatory Compliance | Ensure valve meets industry standards and regulations. | Pharmaceuticals | Safety and quality assurance |

Why Trust Control Valve Sizing Application Your End-to-End Solution

M

Michael Lee

Impressive item! The after-sales personnel demonstrated superb expertise and support.

25 July 2025

L

Logan Turner

Happy with the product quality! The level of support from the team was impressive.

11 June 2025

O

Owen Garcia

The quality is exceptional. The knowledge and professionalism of the support team made a great impression.

01 June 2025

R

Rebecca Nelson

Their customer service team made my purchasing experience seamless. I highly value that!

27 July 2025

D

Diana Torres

The professionalism of the service team stands out. They really know their products!

26 July 2025

G

George Murphy

The product quality is evident, and their service is unbeatable. I highly recommend them!

21 July 2025