Top Butterfly Valve Manufacturers | Reliable Bypass Solutions for Your Needs

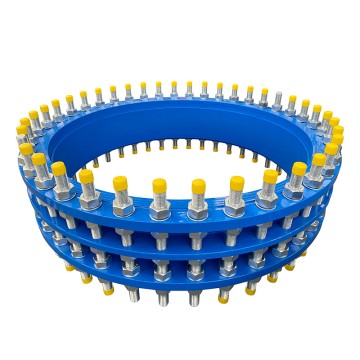

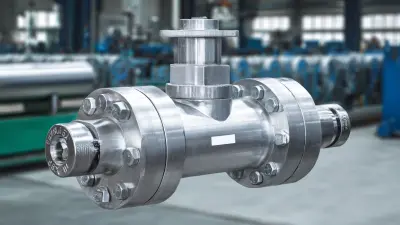

The Bypass Butterfly Valve is a top choice for reliable fluid control. Engineered to meet the demands of various industries, this valve excels in quick and efficient flow regulation. Its robust construction ensures exceptional durability and requires minimal maintenance, making it a wise addition to any system. Produced in partnership with NEWSTAR VALVE (ZHENGZHOU) CO., LTD., our valves undergo thorough testing to guarantee optimal performance under challenging conditions.Key Methods For Bypass Butterfly Valve Manufacturer Now Trending

In the realm of industrial valves, the butterfly valve stands out for its efficiency, cost-effectiveness, and flexibility in handling various flow media. As global demand increases, manufacturers are turning to innovative methods to enhance the design and production of these essential components. Key trending methods among leading Bypass Butterfly Valve manufacturers include the adoption of advanced materials, improved manufacturing technologies, and a focus on customization to meet diverse industrial needs. One significant trend is the integration of smart manufacturing technologies such as automation and computer-aided design (CAD). These tools help in optimizing valve performance and reducing production costs, thus providing buyers with high-quality products at competitive prices. Furthermore, the shift towards incorporating durable materials not only extends the lifespan of butterfly valves but also improves their resistance to corrosion and wear, making them suitable for a broader range of applications. Moreover, the demand for customized solutions is on the rise, with manufacturers offering tailored designs to meet specific requirements across industries such as water treatment, oil and gas, and chemical processing. This trend emphasizes the importance of collaboration between suppliers and clients, ensuring that the final product aligns perfectly with operational needs. As the market evolves, staying ahead of these trends will be crucial for procurement specialists seeking reliable and advanced butterfly valve solutions.

Key Methods For Bypass Butterfly Valve Manufacturer Now Trending

| Method | Description | Advantages | Applications |

|---|---|---|---|

| Cast Iron Construction | Utilizing cast iron for durability and resistance to corrosion. | Cost-effective, long-lasting, and reliable in harsh environments. | Water treatment, HVAC systems, and industrial applications. |

| High-Performance Seals | Incorporating advanced sealing technology to prevent leakage. | Enhanced efficiency and reduced maintenance costs. | Oil and gas, chemical processing, and power generation. |

| Electrically Actuated Valves | Using electric actuators for precise control and automation. | Improved response time and reduced manual labor. | Automation systems in manufacturing and process control. |

| Corrosion-Resistant Materials | Utilizing specialized alloys and coatings to enhance resistance. | Extended lifespan in aggressive environments. | Marine, chemical storage, and wastewater applications. |

| Smart Valve Technology | Implementing sensors and IoT for real-time monitoring. | Enhanced predictive maintenance and operational efficiency. | Smart cities, energy management, and industrial IoT. |

Methods To choose Bypass Butterfly Valve Where Innovation Meets 2025 Trusted by Pros

P

Peyton Taylor

This product is built with care. The customer service team is knowledgeable and very helpful.

08 June 2025

O

Owen Garcia

The quality is exceptional. The knowledge and professionalism of the support team made a great impression.

01 June 2025

S

Susan Mitchell

The customer service team was incredibly helpful and professional. They answered all my questions promptly.

25 July 2025

J

James Wilson

I appreciate the professionalism of the support staff. They were knowledgeable and eager to help.

10 July 2025

L

Laura Richardson

The team was very professional and easy to talk to, making it a pleasant experience.

15 June 2025

J

Julia Morgan

Their after-sales service is commendable. They genuinely care about their customers.

29 June 2025