Leave Your Message

Choosing the right Zero Leakage Butterfly Valve can significantly influence system performance. John Smith, a leading expert in valve technology, states, “The right valve can save time and money in the long run.” His insight highlights the importance of proper selection.

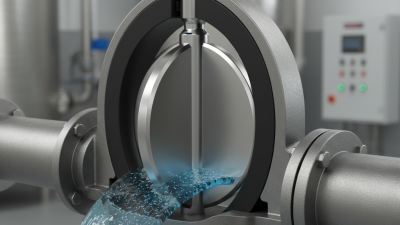

Zero Leakage Butterfly Valves are crucial in many industries. They ensure no fluid leaks through the valve body during operation. This feature is vital for systems that require absolute reliability. In specific applications, even minor leaks can lead to significant operational issues and increased costs.

While many options are available, selection can be tricky. Not every valve labeled "zero leakage" will meet your expectations. Each application has unique demands. Understanding factors like materials, pressure ratings, and operational environments is essential. This process often involves trial and error, resulting in valuable lessons learned. Reflecting on these experiences can lead to better decisions in the future.

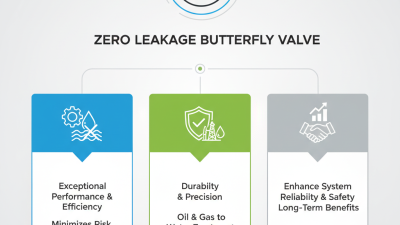

Zero leakage butterfly valves are essential in many industrial applications. These valves prevent fluid escape, ensuring efficiency and safety. Their design allows them to create a tight seal when closed. This quality reduces the risk of leaks, which can lead to significant operational issues. Industries often depend on these valves to maintain system integrity.

Understanding the importance of zero leakage is crucial. Leaks can cause environmental hazards and increase operational costs. Additionally, unplanned downtime can disrupt workflows. The materials used in these valves contribute significantly to their performance. Choosing the right material matters. Different applications might require various materials to withstand pressure and temperature changes.

While zero leakage valves offer many benefits, choosing the best option can be tricky. Not all valves perform equally in every situation. Sometimes, affordability compromises quality. It’s essential to assess each valve's performance in real-world conditions. Many factors influence effectiveness, like installation and maintenance practices. Therefore, a thorough evaluation ensures the selected valve truly meets zero leakage criteria.

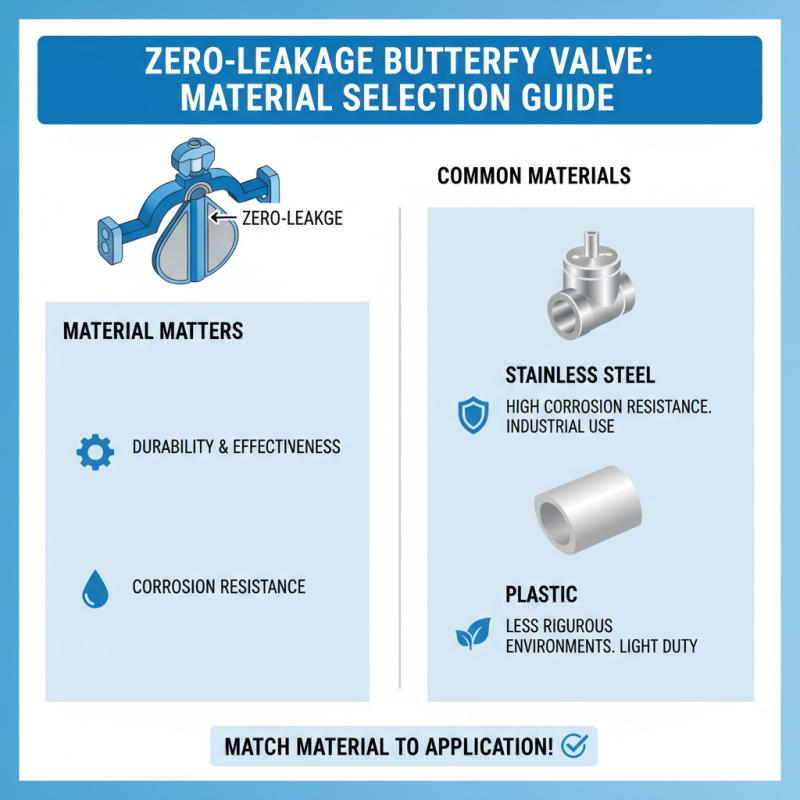

When selecting a zero leakage butterfly valve, it’s crucial to focus on the material. Valve materials influence durability and effectiveness. Consider stainless steel for high corrosion resistance. Plastic may work for less rigorous environments. Ensure that the selected material matches the application requirements.

Another factor is the valve size. Choosing the right size is essential for optimal flow. An undersized valve may cause pressure drops or flooding. An oversized valve can lead to inefficiencies in flow control. Sometimes, these choices require thorough analysis, as well as some trial and error.

Don’t overlook the sealing mechanism. Effective seals are vital for zero leakage. Different designs exist, from resilient to metal-seated options. It’s beneficial to reflect on the operating conditions. Stress from the environment can impact the seals. Selecting the right design involves considering these various factors.

When selecting a zero leakage butterfly valve, material and design variations play crucial roles. The valve's construction directly impacts its sealing capability and durability. Common materials include stainless steel, carbon steel, and plastic composites. Each offers distinct advantages. Stainless steel provides high corrosion resistance. Carbon steel is cost-effective for moderate environments. Plastic options are lightweight but may lack durability.

Effective sealing mechanisms are vital for zero leakage. Many designs incorporate advanced elastomeric seals or metal-to-metal sealing surfaces. These features enhance performance, especially under high pressure. Industry reports suggest that properly engineered seals can reduce leakage rates by up to 90%. However, some designs may still fall short under extreme conditions. Real-world testing reveals inconsistencies that can arise during installation.

Furthermore, users should consider the balloting and flow characteristics of the valve. These factors affect both operational efficiency and energy usage. An ideal flow path creates minimal turbulence. Nevertheless, some configurations may hinder performance, leading to inefficiencies. Understanding these variations is essential for optimal valve performance in diverse applications.

| Material | Design Variation | Leakage Rate | Temperature Range | Pressure Rating |

|---|---|---|---|---|

| Cast Iron | Standard | <1 x 10-6 mbar l/s | -10 to 120 °C | 150 psi |

| Stainless Steel | High-Performance | <1 x 10-8 mbar l/s | -50 to 200 °C | 300 psi |

| Ductile Iron | Double Offset | <1 x 10-7 mbar l/s | -20 to 180 °C | 200 psi |

| PVC | Lined | <1 x 10-5 mbar l/s | 0 to 60 °C | 75 psi |

| Bronze | Wafer | <1 x 10-6 mbar l/s | -10 to 150 °C | 125 psi |

When selecting a zero leakage butterfly valve, understanding testing and certification standards is essential. These standards ensure valves perform optimally under various conditions. The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines for testing these valves' leak-proof properties. According to a recent industry report, valves that meet ANSI/FCI 70-2 standards can significantly reduce leakage rates to less than 0.1% of the maximum flow rate, underscoring their reliability.

Testing procedures typically include pressure testing and temperature variations. It’s important to note that some valves may pass initial tests but fail under real-world conditions. Regular performance assessments can help identify these discrepancies. A study from the Valve Manufacturers Association highlighted that 20% of valves installed in the field might not meet initial specifications. This raises questions about the importance of continuous monitoring and reevaluation of existing standards.

Incorporating rigorous certification processes into the selection process is crucial. Many manufacturers claim their products are zero leakage, but ongoing certifications significantly enhance consumer confidence. In a field with dynamic regulations, keeping abreast of changes in testing protocols is equally important. One must be cautious with claims of perfection. Actual performance often reveals complexities that testing does not always address.

Maintaining zero leakage butterfly valves is crucial for reliability and performance. Regular inspections can prevent leaks and ensure proper functioning. A study by the Valve Manufacturers Association (VMA) highlights that improper maintenance can lead to a 30% decrease in valve lifespan.

Perform routine checks on seals and seats. Any signs of wear can indicate potential issues. Lubrication should be part of your maintenance routine, as a lack of it can lead to corrosion and reduced efficiency. Studies show that under-lubricated valves have a failure rate 40% higher than well-maintained counterparts.

Operators should keep spare parts on hand. Unplanned downtime can cost companies thousands of dollars. Address small issues promptly to avoid costly repairs later. Monitoring the valve's performance through data analysis can provide insights into its condition. Neglecting this can result in operational inefficiencies.

Always reflect on your maintenance strategies. What can you improve?