Bi-Directional Zero Leakage AWWA C504 Butterfly Valve

Product description

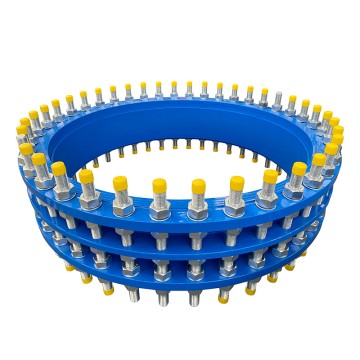

♦ Valve design, materials and testing conform to requirements of AWWA C504

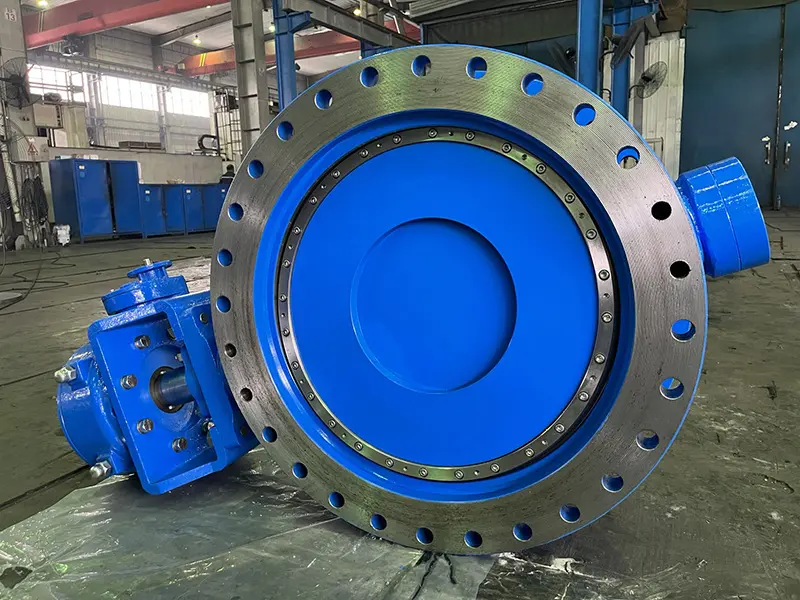

♦ Robust body with min. shell thickness to the standard, and of ductile iron ASTM A536 grade 65-45-12 or grade 60-40-18

♦ Body with flange X flange ends of flat face, flange drill to ASME B16.1, ASME B16.5, AWWA C207

♦ Victaulic grooved ends or other type of connection ends are also available.

♦ Solid single disc or lattice disc(for larger sizes) both with high strength, greater free flow area.

♦ Higher Cv and lower head loss/pressure drop

♦ Rubber seat located on disc, the full 360°uninterruptible seal ring secured with a retainer ring for bidirectional service up to full rated pressure, and easy for adjustment and replacement without special tools.

♦ Body seat ring made of stainless steel weld, micro-finished with long service time.

♦ Two piece, stub-type shaft of corrosion resistant material SS630, other materials available as request.

♦ Sleeve-type bearing in both trunnions/hubs of valve body, self-lubricating, maintenance free.

♦ Multiple O rings on bearing bush and V shaft packing form reliable shaft sealing system.

♦ V type shaft packing and extended bonnet design, to realize adjustment or complete replacement of packing without disturbing any part of valve or actuator assembly.

♦ Disc to shaft connection by taper pins. Other methods available as request.

♦ Cycle tested per AWWA C504 requirements, proven reliability over the life of the valve

♦ Actuation options: Manual gearbox with handwheel or chainwheel,

Gearbox with ISO5210 top works for electric actuator,

Electric actuator

Hydraulic or pneumatic cylinder

♦ Protection coating: fusion bonded epoxy coating non-toxic to potable water approved from WRAS/NSF.

♦ Other options:

- Shaft locking device(during equipment maintenance, even removing the valve operation mechanism, the valve can be kept in full close/full opening position.

- The material solution of Aluminum bronze/nickel aluminum bronze( such as ASTM B148 C95400/C95500/C95800 body & disc and nickel-copper alloy(such as Monel k400,Monel k500 etc.) shaft is available for desalination of sea water project.

- Rubber lining(ebonite lining)

- Extended bonnet

- Extended spindle from valve drive shaft for vertical installation, and from gear spindle for horizontal installation. Rigid and high strength design, no need additional support and reinforced accessories.

AWWA C504 BUTTERFLY VALVE

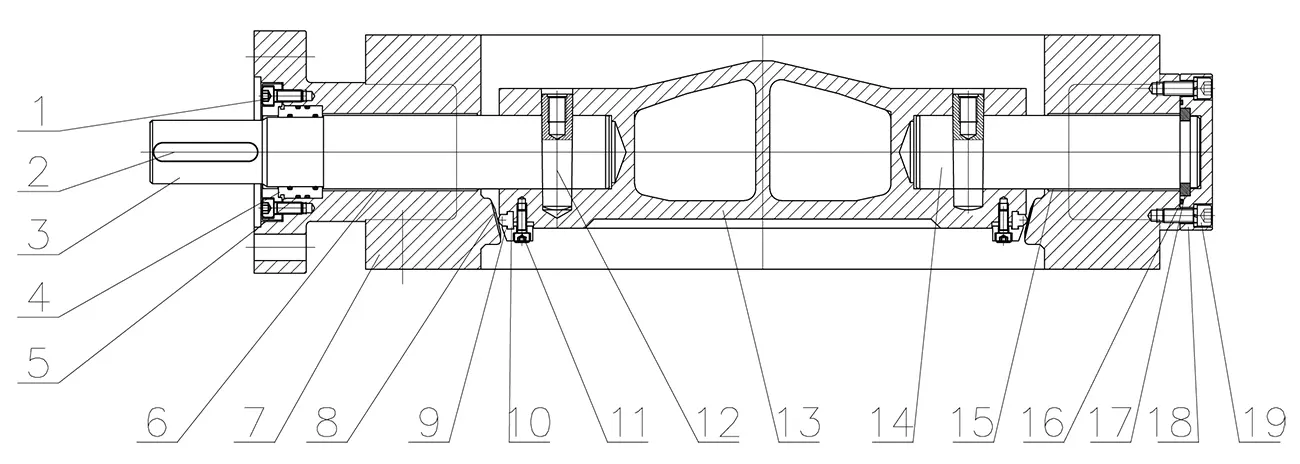

Materials of component

|

No |

NAME |

MATERIAL* |

SPECIFICATION |

REMARKS |

|

|

1 |

Screw |

Stainless Steel |

A2-70(SS304),A4-70(SS316) |

||

|

2 |

Key |

Stainless Steel |

SS420 |

||

|

3 |

Upper Shaft |

Stainless Steel |

SS420,SS630 |

||

|

4 |

Packing Gland |

Carbon steel |

A36 |

||

|

5 |

0 ring |

Rubber |

EPDM, NBR |

||

|

6 |

Shaft Bearing |

Stainless Steel/bronze+PTFE |

|||

|

7 |

Valve Body |

Ductile Iron |

65-45-12, 60-40-18 |

||

|

Carbon steel |

WCB |

||||

|

8 |

Body seat |

Stainless steel |

Cr-Ni alloy / Ni welded |

||

|

9 |

Disc Seal Ring |

Rubber |

EPDM, NBR |

||

|

10 |

Retainer Ring |

Stainless Steel |

SS304,SS316 |

||

|

11 |

Screw |

Stainless Steel |

A2-70(SS304),A4-70(SS316) |

||

|

12 |

Pin |

Stainless Steel |

SS420 |

||

|

13 |

Valve Body |

Ductile Iron |

65-45-12, 60-40-18 |

||

|

Carbon steel |

WCB |

||||

|

14 |

Lower Shaft |

Stainless Steel |

SS420,SS630 |

||

|

15 |

Shaft Bearing |

Stainless Steel/bronze+PTFE |

|||

|

16 |

0 ring |

Rubber |

EPDM, NBR |

||

|

17 |

Collar |

Copper |

QAI9-2 CC331G |

||

|

18 |

End Cover |

Carbon steel |

A36 |

||

|

19 |

Bolt |

Stainless Steel |

A2-70(SS304),A4-70(SS316) |

||

(Other materials such as carbon steel, st. steel, duplex SS, al-bronze are available on request.)

★ Coating: fusion bonded epoxy coating, min. thickness 250 micron Suitable medium: drink water, sea water, TSE water, low-corrosive liquid, air etc.

★ Suitable temperature: 0 ~ 80 ℃

★ Pressure test to AWWA C504: Leakage rate: Class A (Zero leakage) in both direction

★ 100% testing before delivery

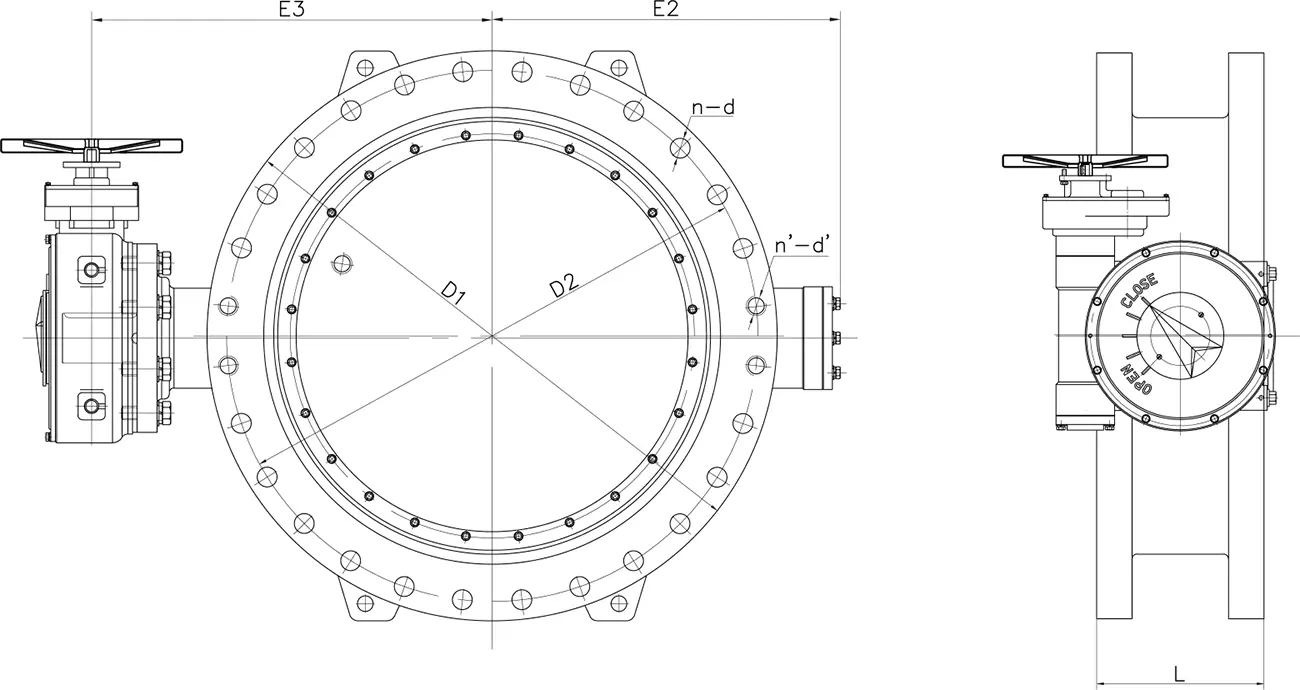

AWWA C504 BUTTERFLY VALVE

Dimensions*/Class 150B/250B

|

Size |

D1 |

D2 |

n-Φd / n'-Φd' |

L |

E2 |

E3 |

Weight kgs |

|

6'' |

280 |

241 |

8-Φ0.875'' |

127 |

164 |

225 |

35 |

|

8'' |

345 |

299 |

8-Φ0.875'' |

152 |

198 |

272 |

55 |

|

10'' |

405 |

362 |

12-Φ1'' |

203 |

230 |

328 |

98 |

|

12'' |

485 |

432 |

12-Φ1'' |

203 |

254 |

351 |

136 |

|

14'' |

535 |

476 |

12-Φ1.125'' |

203 |

295 |

407 |

195 |

|

16'' |

595 |

540 |

12-Φ1.125''/4-1''8UNC |

203 |

334 |

437 |

220 |

|

18'' |

635 |

578 |

12-Φ1.25''/4-1.125''8UN |

203 |

368 |

488 |

260 |

|

20'' |

700 |

635 |

16-Φ1.25''/4-1.125''8UN |

203 |

400 |

530 |

335 |

|

24'' |

815 |

749 |

16-Φ1.375''/4-1.25''8UN |

203 |

480 |

548 |

465 |

|

28'' |

925 |

864 |

24-Φ1.375''/4-1.25''8UN |

292 |

563 |

640 |

620 |

|

30'' |

985 |

914 |

24-Φ1.375''/4-1.25''8UN |

305 |

586 |

669 |

805 |

|

32'' |

1060 |

978 |

24-Φ1.625''/4-1.5''8UN |

305 |

623 |

698 |

890 |

|

34'' |

1110 |

1029 |

28-Φ1.625''/4-1.5''8UN |

305 |

660 |

745 |

1000 |

|

36'' |

1170 |

1086 |

28-Φ1.625''/4-1.5''8UN |

305 |

698 |

789 |

1230 |

|

40'' |

1290 |

1200 |

32-Φ1.625''/4-1.5''8UN |

305 |

766 |

882 |

1700 |

|

44'' |

1405 |

1314 |

36-Φ1.625''/4-1.5''8UN |

381 |

795 |

1008 |

1900 |

|

48'' |

1510 |

1422 |

40-Φ1.625''/4-1.5''8UN |

381 |

910 |

1038 |

2600 |

|

52'' |

1625 |

1537 |

40-Φ1.875''/4-1.75''8UN |

381 |

1008 |

1132 |

3100 |

|

56'' |

1745 |

1651 |

44-Φ1.875''/4-1.75''8UN |

381 |

1063 |

1253 |

3800 |

|

60'' |

1855 |

1759 |

48-Φ1.875''/4-1.75''8UN |

381 |

1120 |

1300 |

4800 |

|

72'' |

2195 |

2096 |

56-Φ1.875''/4-1.75''8UN |

457 |

1416 |

1602 |

5600 |

-Flange dimensions and drilling to ASME B16.1 class125/AWWA C207

-All the outline dimensions and weight only for reference. If need, please contact us for exact data.

-Please contact us for other details or larger sizes.

Product Display